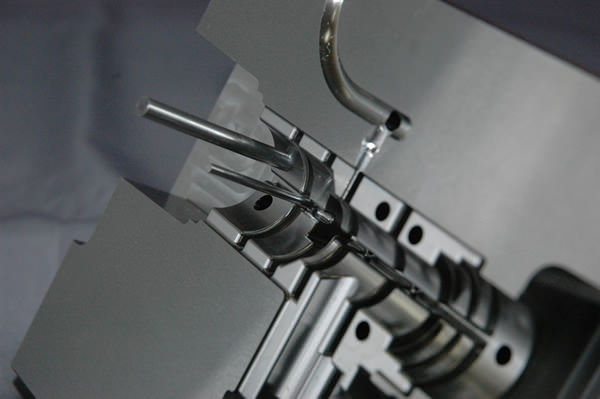

Ejector pin hole drilling in plastic mold (HRC52)

Machining conditions

| Work material | STAVAX HRC52±2 |

|---|---|

| Coolant | water soluble cutting oil |

Machining process 1

| Tool used | TOGLON HARD SP |

|---|---|

| Van code | 90TGHSP3CBALD |

| Process | Spot drilling |

| Comparisson tool | none |

| Diameter | φ2.5mm |

| Drilling depth | 1mm |

| Cutting speed | 25m/min |

| Spindle speed | 3200min-1 |

| Feed amount | 0.04mm/rev |

| Feed speed | 128mm/min |

Machining process 2

| Tool used | TOGLON Hard Long Drill |

|---|---|

| Van code | TGHDL2CBALT |

| Process | Through hole drilling |

| Comparisson tool | none |

| Diameter | φ2mm |

| Drilling depth | 40mm |

| Cutting speed | 25m/min |

| Spindle speed | 4000min-1 |

| Feed amount | 0.04mm/rev |

| Feed speed | 160mm/min |

| Step length | 0.5mm |

Machining process 3

| Tool used | TOGLON Hard Long Drill |

|---|---|

| Van code | TGHDL4CBALT |

| Process | Through hole drilling |

| Comparisson tool | none |

| Diameter | φ4mm |

| Drilling depth | 40mm |

| Cutting speed | 25m/min |

| Spindle speed | 2000min-1 |

| Feed amount | 0.06mm/rev |

| Feed speed | 120mm/min |

| Step length | 0.5mm |

Test result

The ejector pin hole could be drilled into the pre-hardened steel without problems.